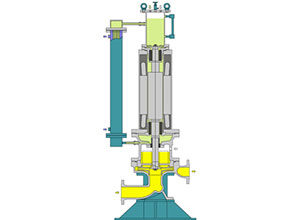

The Czech pump manufacture, Hermag, has vast expertise when it comes to canned motor pumps for demanding applications. Hermag’s sealless pumps are available in various materials including cast iron, stainless steel, hastelloy, and titan, making them suitable for oil and gas, nuclear, and the chemical industry.

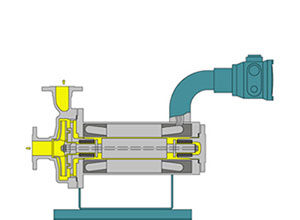

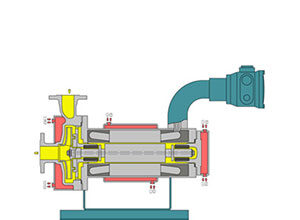

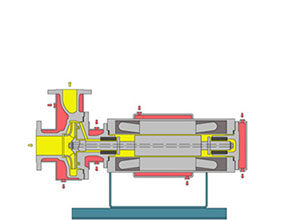

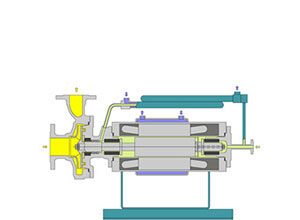

Hermag pumps employ a hermetically sealed design, which makes them completely leak-free, and safe to both staff and the environment. Their pumps furthermore use hydrodynamic slide bearings that are lubricated by the liquid. Hence, there is no need to monitor lubrication levels, as pumps run seamlessly at all times.

To learn more visit : Hermag

See Hermag’s brochure here or check the pump specifications in the table below.

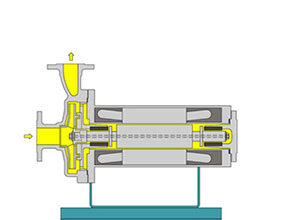

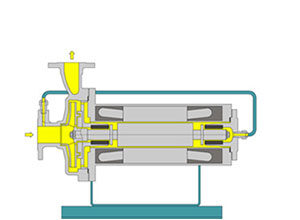

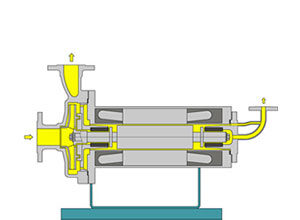

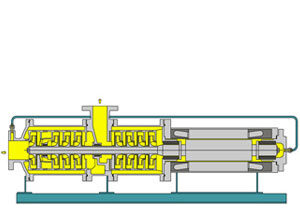

Standard

| Model | Max. Flow | Max. Head | Temperature |

|

|---|---|---|---|---|

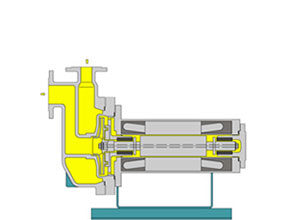

| CH (hollow shaft) | 300 m³/h | 110 m | 120 °C |

| CE (external circulation) | 600 m³/h | 165 m | 120 °C |

| CR (reverse circulation) | 350 m³/h | 160 m | 120 °C |

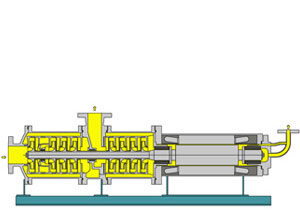

| CEM (external circulation - multistage) | 100 m³/h | 600 m | 120 °C |

| CRM (reverse circulation – multistage) | 100 m³/h | 600 m | 120 °C |

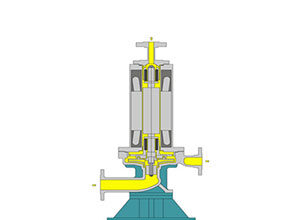

| CRV (vertical reverse circulation) | 350 m³/h | 125 m | 120 °C |

| CP (self-priming) | 50 m³/h | 50 m | 120 °C |

High Temperature / High Melting Point

| Model | Max. Flow | Max. Head | Temperature |

|

|---|---|---|---|---|

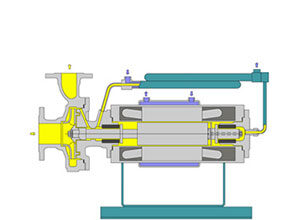

| CT (high temperature) | 650 m³/h | 150 m | 450 °C |

| CI (high temperature) | 300 m³/h | 160 m | 400 °C |

| CMI (high melting point) | 220 m³/h | 90 m | 400 °C |

| CM (high melting point) | 300 m³/h | 90 m | 120 °C |

Slurry Handling

| Model | Max. Flow | Max. Head | Temperature |

|

|---|---|---|---|---|

| CS (slurry handling) | 380 m³/h | 120 m | 400 °C |

| CSG (gas seal slurry handling) | 300 m³/h | 160 m | 400 °C |